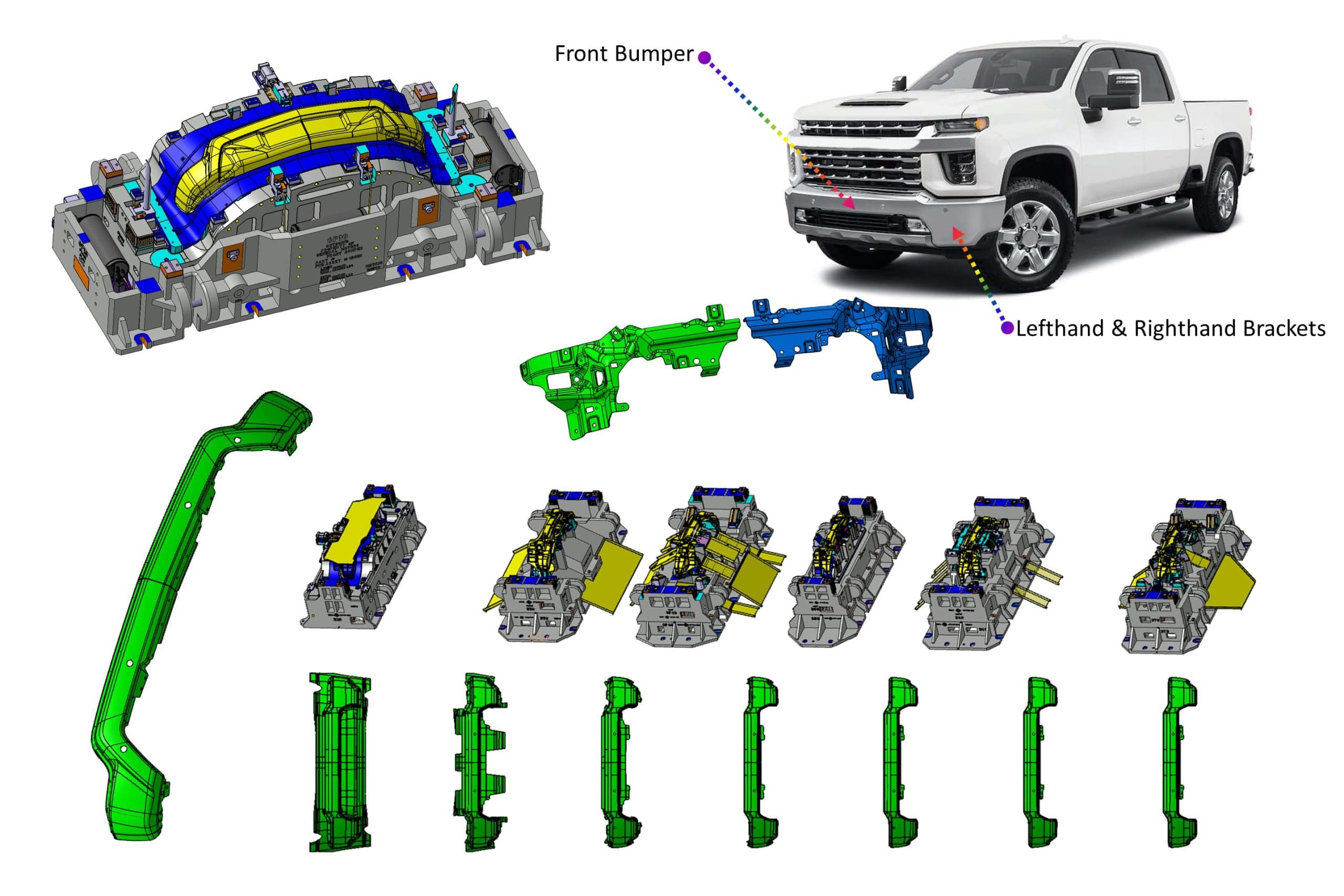

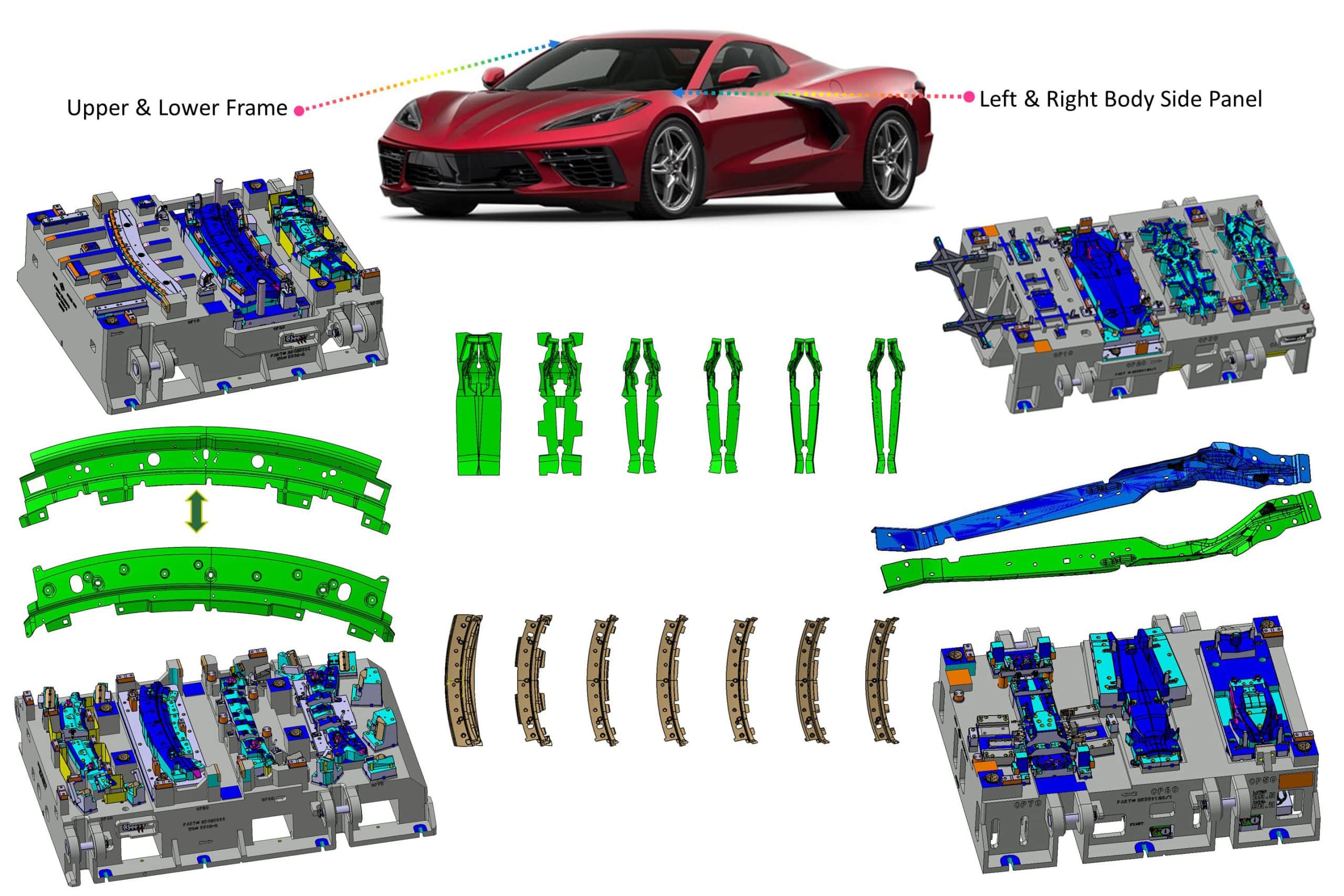

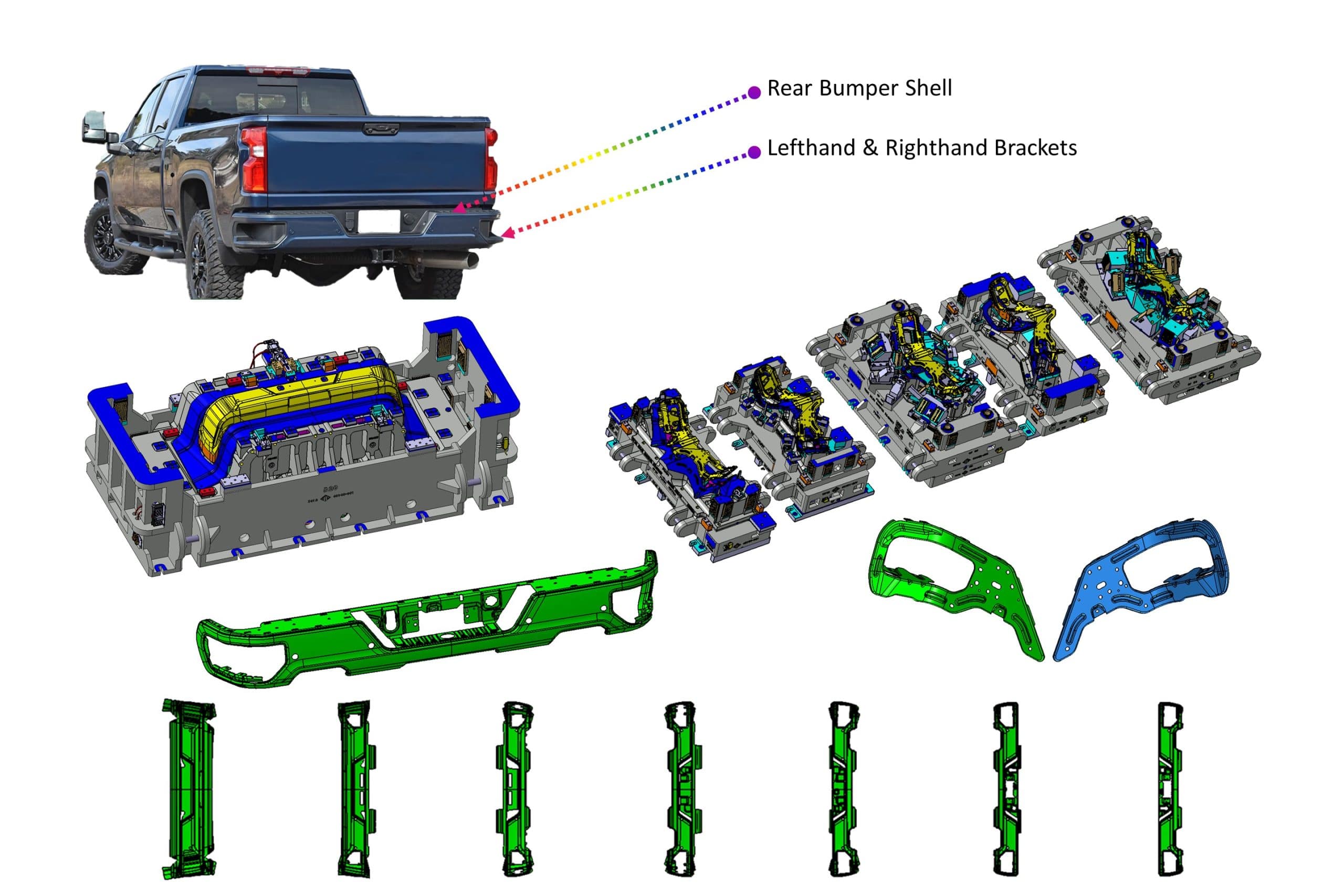

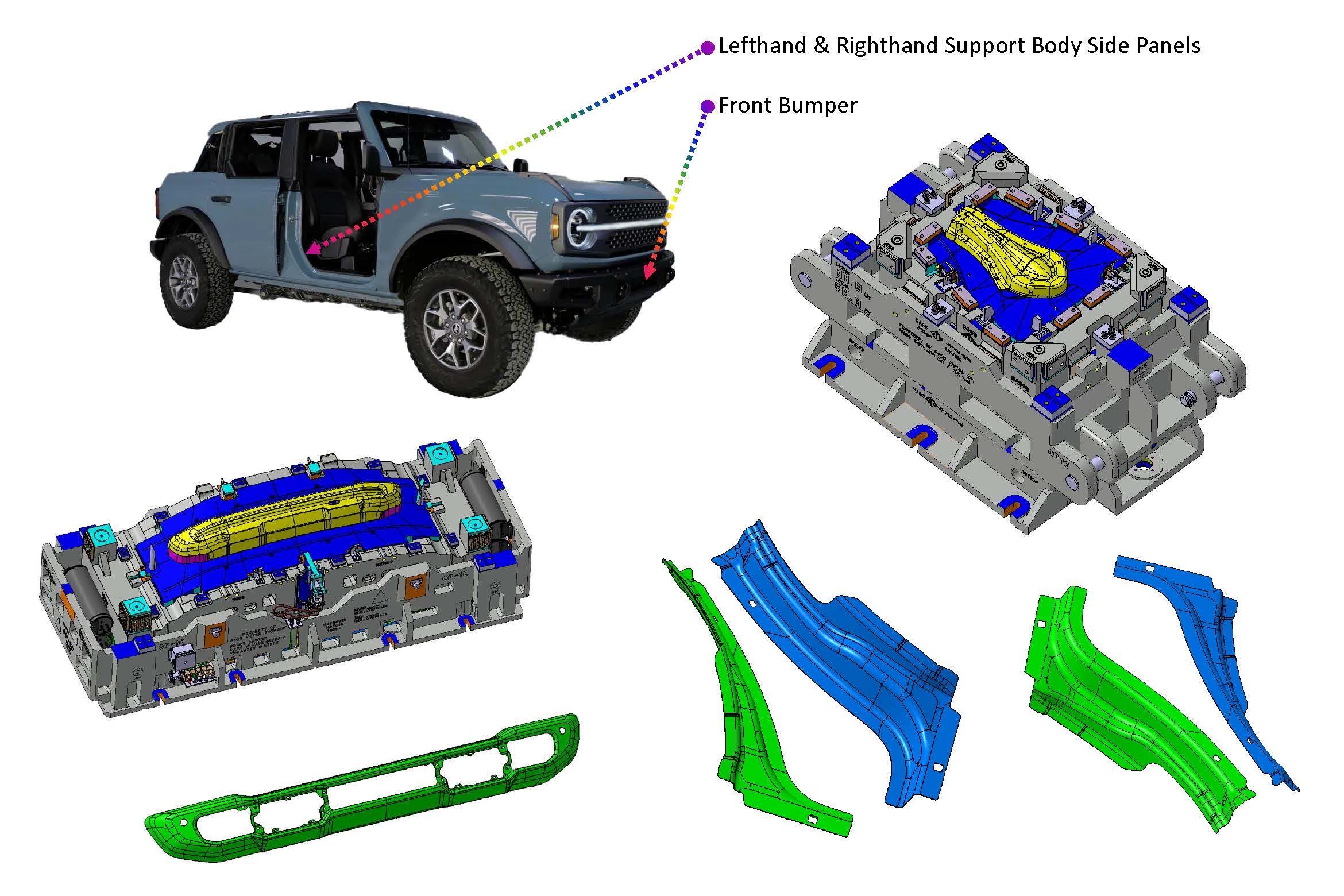

DESIGNERS & BUILDERS OF HIGH QUALITY STAMPING DIES SINCE 1946

CAPABILITIES

Tryout Presses

We have the tryout press capability to match our customers’ needs. Computerized Autoform die simulation software facilitates the tryout process. Capability studies are conducted to ensure the customer’s quality standards are met.

We are very experienced with both advanced high strength and dual phase materials and have tryout capabilities to over 2,100 tons accommodating dies up to 96″ wide X 240″ long. Simple and complex progressive dies from 24″ X 36″ to 72″ X 200″ and weighing more than 25 tons may have up to 6″ draw depths and 12″ – 15″ pitches. We build 3-9 station transfer dies requiring ram tonnages to over 2,100 tons and up to 30 strokes per minute. Traditional transfer as well as walking beam type including servo drive control.

- 1 – Niagara 2200 Ton 96″ X 240″, SH 42″-60″

- 1 – Verson 2000 Ton 96″ X 204″, SH 44″-66″

- 1 – Niagara 1100 Ton 72″ X 144″, SH 22.75″ – 47.5″

- 2 – Danly 800 Ton 72″ X 144″, SH 35″ – 71.5″

- 3 – Danly 800 Ton 66″ X 120″, SH 18″ – 41.25″

- 1 – Danly 1600 Ton 72″ X 144″, SH 44″ – 62″

- 3 – Niagara 300 Ton 48″ X 90″, SH 28.75″ – 39.87″/li>

- 1 – 400 Ton Hydraulic 72″ X 87″, SH 24.5″ – 48″

- 1 – Dake 150 Ton Hydraulic 50″ X 82″, SH 15.5″ – 46.37″