DESIGNERS & BUILDERS OF HIGH QUALITY STAMPING DIES SINCE 1946

CAPABILITIES

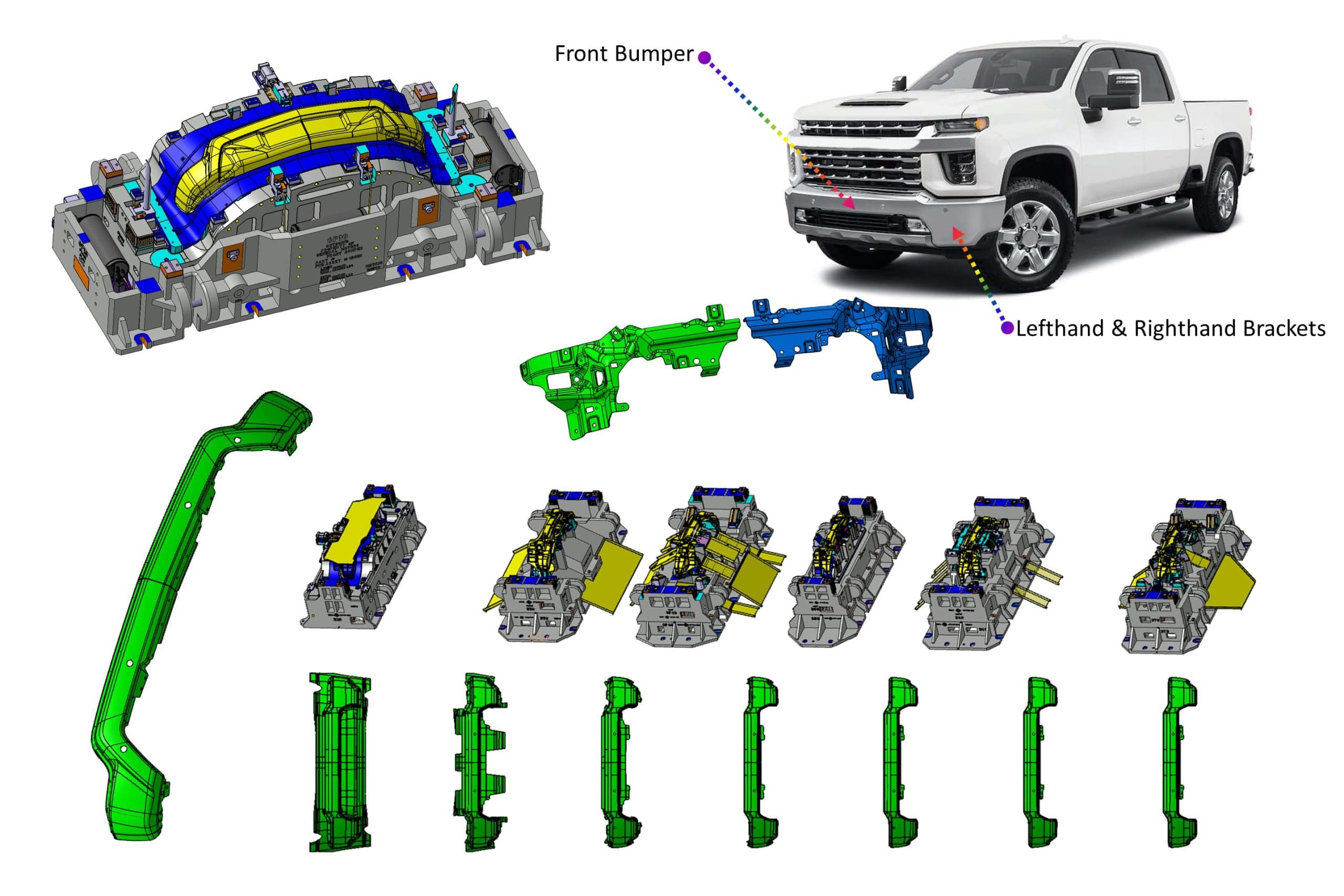

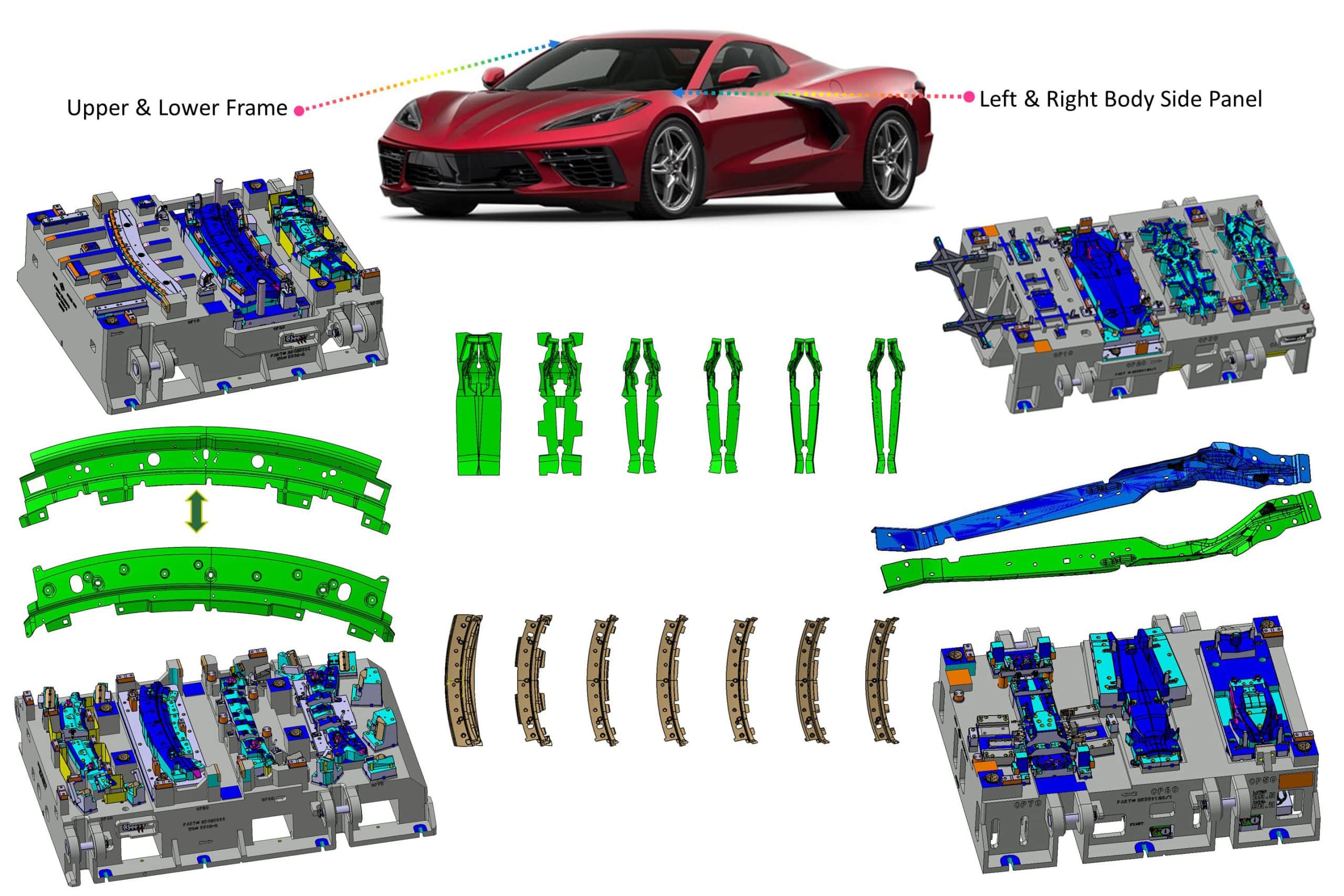

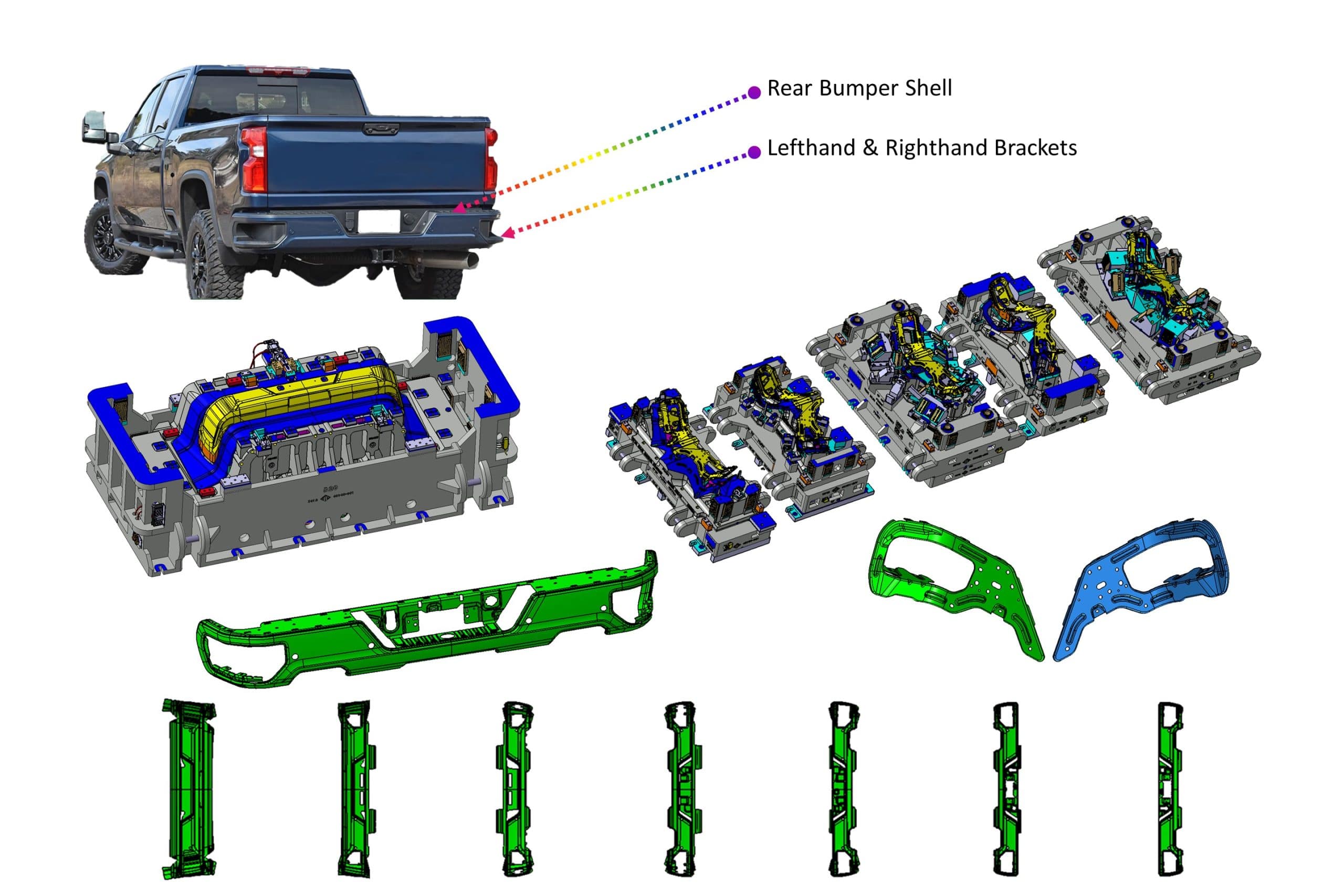

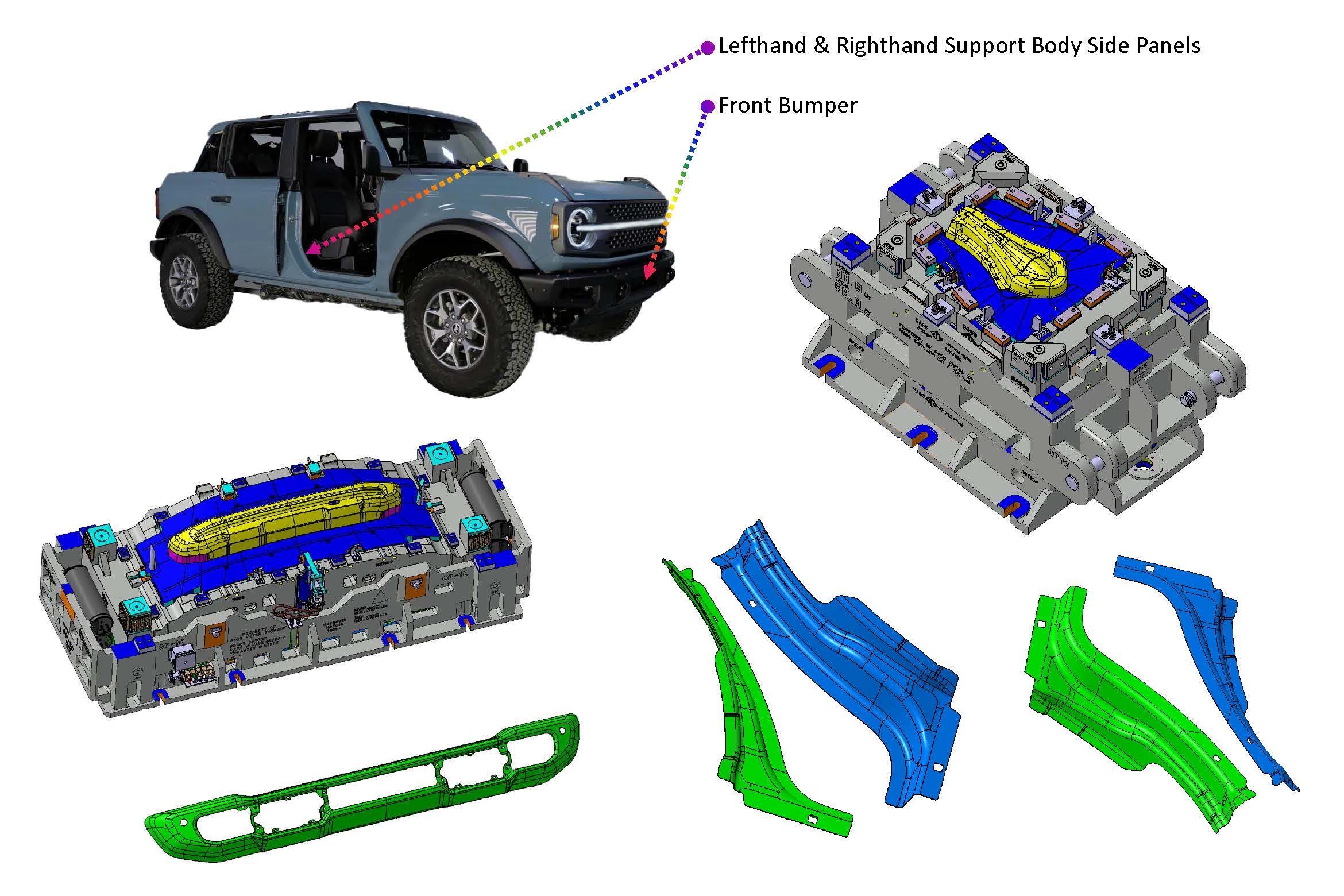

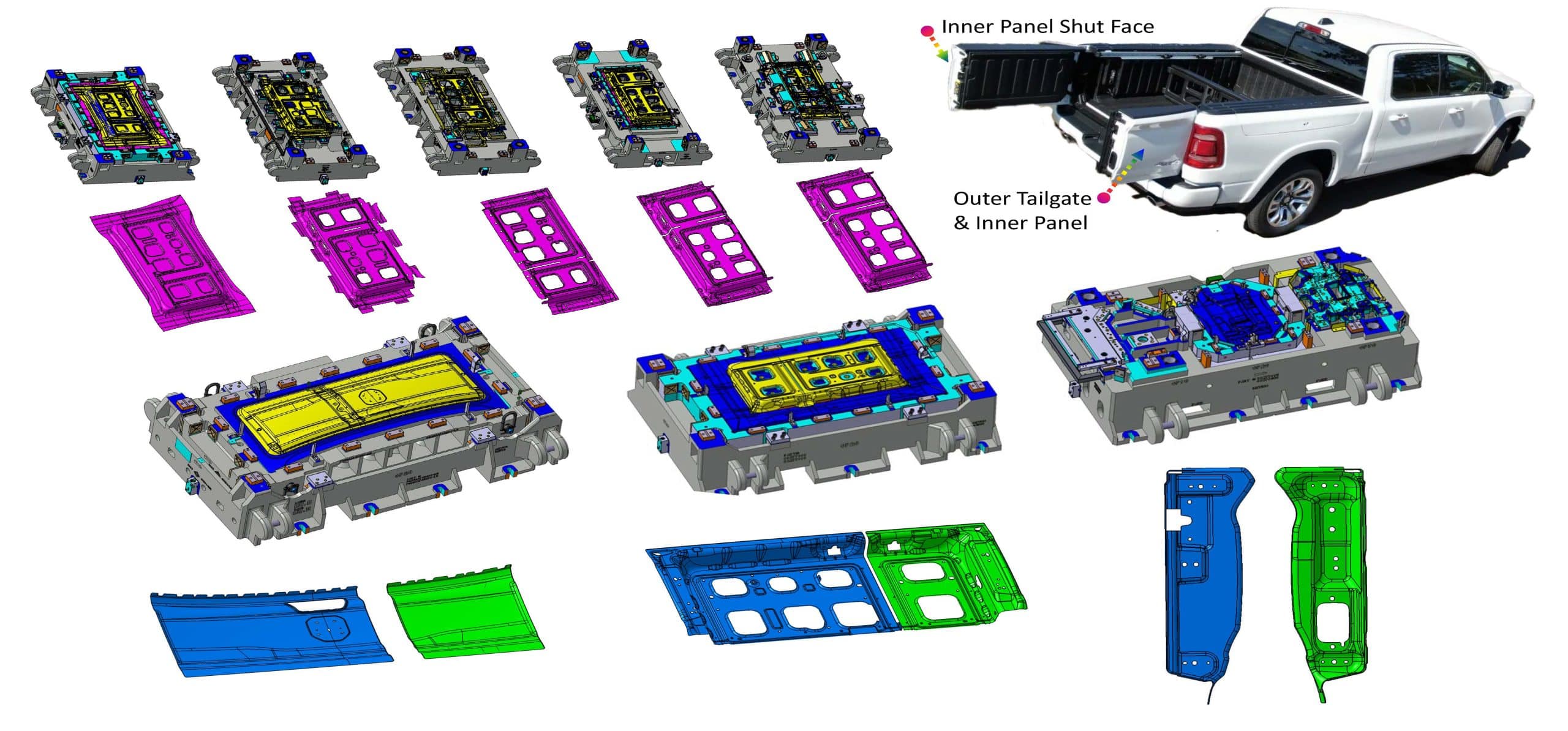

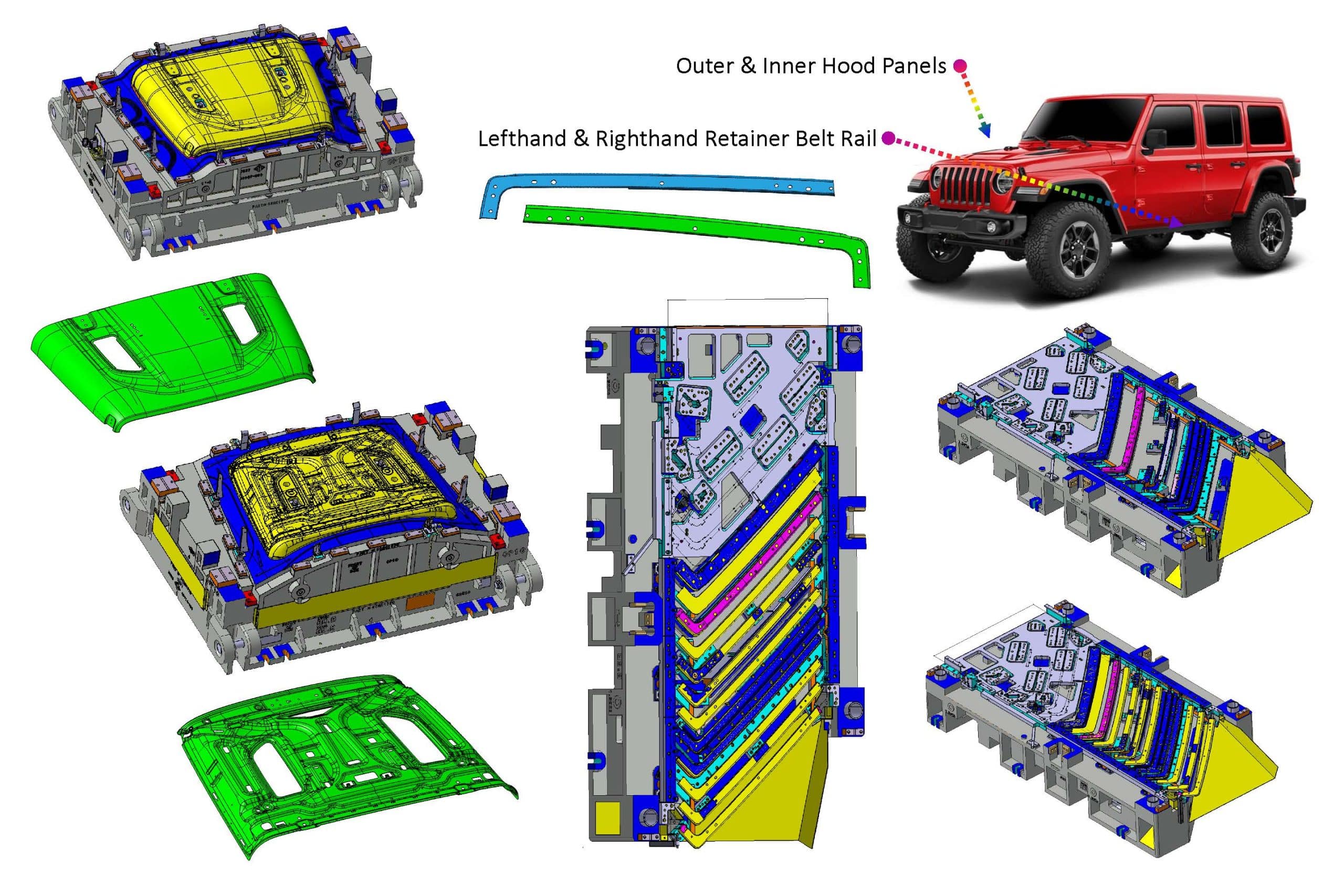

METAL STAMPING DIES

Our high quality, close tolerance tooling includes line dies, progressive dies, and transfer dies for any industry. Greenville Tool & Die is experienced with the development of tooling for parts designed for advanced high strength and dual phase materials. Our tryout capabilities span to over 2,100 in sizes to 96″ wide x 240″ long. We are experts in the design and building of all types of metal stamping dies including draw dies, tube dies, blank dies, pierce dies, trim dies, and form dies.

Line Die – Line dies are used to make low-volume parts not requiring an automated tool or die. They may also be used to make large parts which are not practical to be run from several dies in a single press. These parts are then often run in “tandem line” presses combining automation to automatically move the parts between these presses

Progressive Die – for higher volume parts needing to run automatically at high rates of speed (strokes per minute).

GTD has designed and built hundreds of progressive dies for parts with a wide range of material thicknesses and coil widths. We also design to fit your press(es) and can also design to do curling and hemming. We can provide progressive dies to handle material thicknesses from as thick as 5.0mm (.200″) high strength steel to as thin as 0.25mm (.010″) thick aluminum and stainless steel.

Transfer Die – typically used for high volume, medium sized parts such as cowl panels, pillars, control arms, and heat shields. Our custom designed walking beam transfer dies can be used in tube applications as well as stamped parts.

Material thicknesses range from .254mm (.010″) aluminum to 5mm (.200″) steel. Greenville Tool & Die can design and build your transfer bars and fingers to fit your transfer system, or we can work with your automation supplier to integrate these with the dies we are designing and building for you. We also have experience with the building of gravity fed scrap removal systems either of shaker or conveyor type for through the press bolster, or off the edge of the bolster.